You create a product — and it’s a great product! However, countless other companies make similarly great products. How do you gain a competitive edge in a saturated market? The secret is to employ a digital transformation strategy.

According to Gartner, digital transformation is “the use of digital technologies to change a business model and provide new revenue and value-producing opportunities.” Now the “what” of how to gain a competitive edge is established, but there needs to be a way to get from point A to point B. Product Lifecycle Management (PLM) is a solution.

There is an important distinction to be made: Not all PLM systems spur digital transformation. A PLM system could be as rudimentary as having an excessive number of spreadsheets strewn between countless devices and people. This outdated system is NOT the backbone of digital transformation. Advanced PLM software that centralizes information — and digitizes information and processes — to streamline production, minimize cost, and maximize profitability IS the backbone.

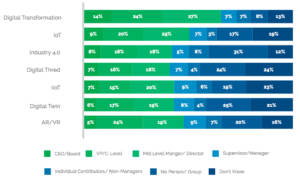

We recently surveyed roughly 150 companies of varying sizes to dig deeper into current trends to gauge the current state of digital transformation and companies related progress. According to our recent report, PLM & The Digital Enterprise, 60% of manufacturers see PLM as a critical or significant contributor to their digital transformation strategy.

PLM software helps enable your digital transformation strategy in a myriad of ways, all of which lead to improving your bottom-line.

Reigning in Cost

PLM software helps a company stay within the parameters of a budget in two ways: Preventing costly mistakes upfront and predicting the cost of future projects accurately.

Costly mistakes upfront can derail a product build for an extended period of time, making a company lose out on both valuable time and money. Employing the digital twin is just one way PLM can help you stay within budget.

- Utilizing the Digital Twin: The digital twin denotes a computerized replica of a physical asset. The traditional method of testing a product follows three stages: creating a prototype, testing that prototype, and returning to the design process to address the failures of that prototype. The integration of computer-aided design (CAD) into PLM software allows companies to test a product digitally instead of creating physical prototypes — a significantly less expensive process.

On a universal scale, PLM software prevents miscommunications between departments — as well as a loss of information — both of which can result in hefty unforeseen costs.

Along with preventing mistakes at the beginning of the production process, PLM software can aid in projecting the cost of future projects. This can be chalked up to how PLM draws on the digital thread.

- Utilizing the Digital Thread: The digital thread refers to “the communication framework that allows a connected data flow and integrated view of the asset’s data throughout its lifecycle across traditionally siloed functional perspectives.” For example, if you are tasked with planning the budget for a car’s product lifecycle, the budget will be based on the cost of the same model from previous years. It must take into account everything from design work to physical production. If pieces of data are missed, the budget can be grossly underestimated. This comprehensive system for data storage ensures the most accurate cost projections.

Staying within budget is reason enough to pat yourself on the back, but how does this help you reach long-term goals — particularly profitable growth?

Surpass Growth Goals

Profitable growth is something that all organizations chase. To support this growth, an organization must lower the production cost — as covered previously — and revenue must be increased. PLM helps achieve this by facilitating the Internet of Things.

- Utilizing the Internet of Things: IoT is the connection of everyday items to the internet. This enables manufacturers to gather real-time data on a product. PLM can facilitate data collection, which in turn, boosts product quality that fosters customer loyalty and help identify features and products customers will buy.

PLM can employ IoT to take all the guesswork out of product creation. This paves the road to profitable growth.

The Bottom-line

The goal of digital transformation is to use technology to reinvent a process that improves efficiency and lowers cost. PLM software enables this goal at every step of a product’s life. It creates a centralized information system that eliminates miscommunications and reduces production time while decreasing production costs, which increases profit margins. A process that used to be bogged down by frustrating trial-and-error is now reinvented to be remarkably efficient and enable digital transformation.

We’ve seen the idea of PLM evolve throughout the years. The technology has caught up to the vision of PLM, and we are at a pivotal point in realizing the goal of digital transformation. Companies that are looking to create or update an efficient PLM Strategy need to partner with a company that has a proven track record. Contact us to learn more about how we can help. You can also access our report, “PLM & the Digital Enterprise,” to further understand how PLM could enable your company’s digital transformation.